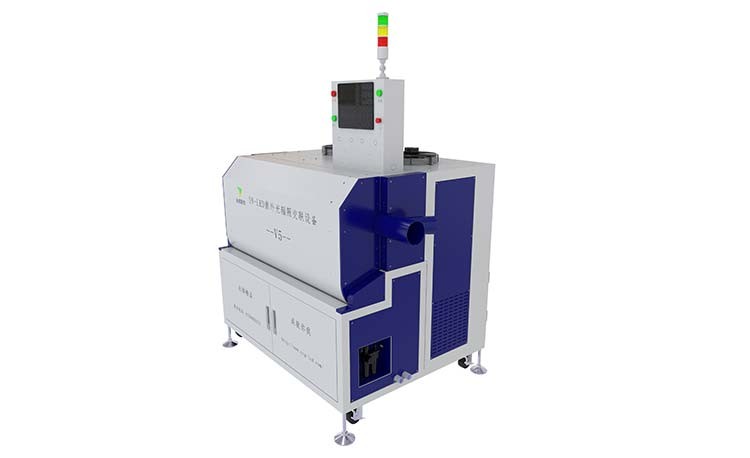

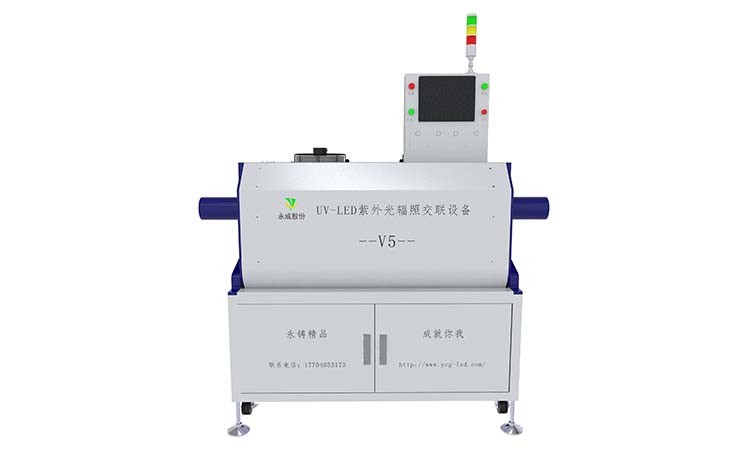

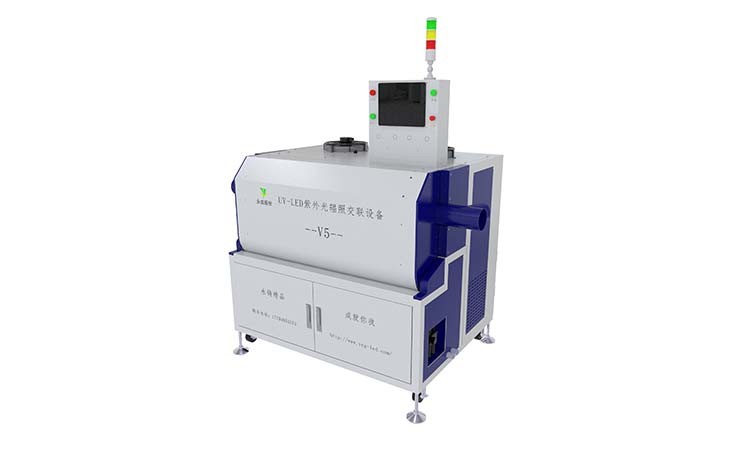

The process flow of the UV-irradiated cable cross-linking equipment is to use single-wavelength ultraviolet light as the radiation source, extrude and wrap the mixed photo-cross-linked polyolefin ingredients on the conductive core, and then immediately enter the special irradiation equipment In the molten state UV cross-linking. The insulated wire cores cross-linked by light irradiation can undergo cooling treatments at different temperatures and other subsequent processing to obtain photo-cross linked polyolefin insulated wire and cable products. The UV-irradiated cable cross-linking equipment only needs to be slightly modified on the original ordinary extrusion production line.

1、Equipment Feature

(1)Adopt Pneumatic flip to start tunnel structure, convenient for operation, cleaning, and wire taking;

(2)Using smart touch man-machine interface, monitoring data, operating button power settings are all done on the touch screen interface

(3)One-key start function and single start coexistence

(4)The cooling method adopts the refrigeration machine, the circulating medium adopts the special antifreeze liquid for the car; the external smoke removal mechanism is exhausted to the outside through the air duct;

(5)The equipment power can be set within range of 0~100%

2、Equipment main Technical Parameter

(1)Equipment total power: 22kW

(2)Effective diameter of irradiated area: 30mm

(3)Effective irradiation length: 1m

(4)Power supply: AC 380V

(5)Irradiation box size:2010*1100*1650mm(LxWxH)